Program Description

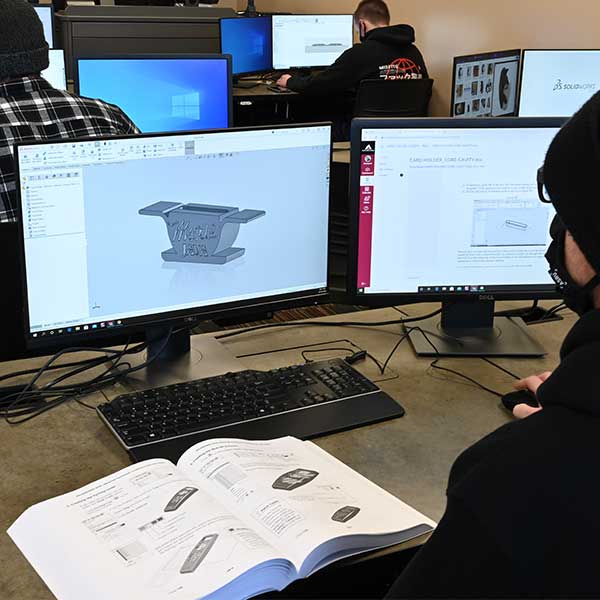

This 11-month program prepares students for employment as industrial plant maintenance mechanics or millwrights. Students learn the basics of maintenance fabrication installation and alignment of equipment used in modern industrial and manufacturing plants.

Theory classes provide technical information pertaining to welding hydraulics electricity rigging pipe fitting mechanical drive/transmission systems pumps and equipment installation and alignment.

Laboratory classes teach students to skillfully perform welding and fabrication tasks as well as the maintenance of hydraulic electro/mechanical systems. The well-equipped lab includes the latest technology in laser alignment of rotating equipment. Blueprint reading and shop math are taught and used in all areas of training. A general education component of English occupational relations and math are integrated into the program. Successful completion of the first semester or instructor permission is required to continue into the second semester and summer session.

Interested students should possess basic math skills (knowledge of basic Algebra and Geometry) Reading skills and have a keen interest in mechanics. Placement in specific English and math classes is determined by the college assessment test.

Parker Technical Education Center

Classes for this program are located in Rathdrum, Idaho, 12 miles from Coeur d’Alene at the Parker Technical Education Center

Chris Gordon

Industrial Mechanic/Millwright Instructor

Office: Parker Technical Education Center 183

Phone: (208) 769-3460

Email: christopher.gordon@nic.edu